Please wait while flipbook is loading. For more related info, FAQs and issues please refer to DearFlip WordPress Flipbook Plugin Help documentation.

WELCOME TO

MAHATTA TRADING COMPANY W.L.L

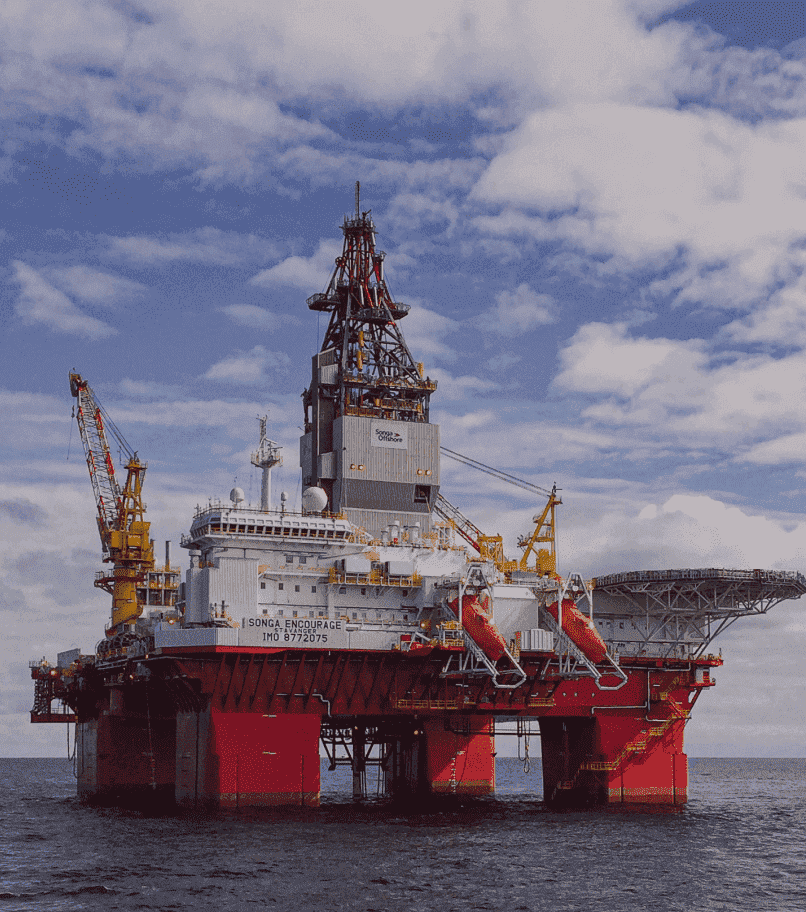

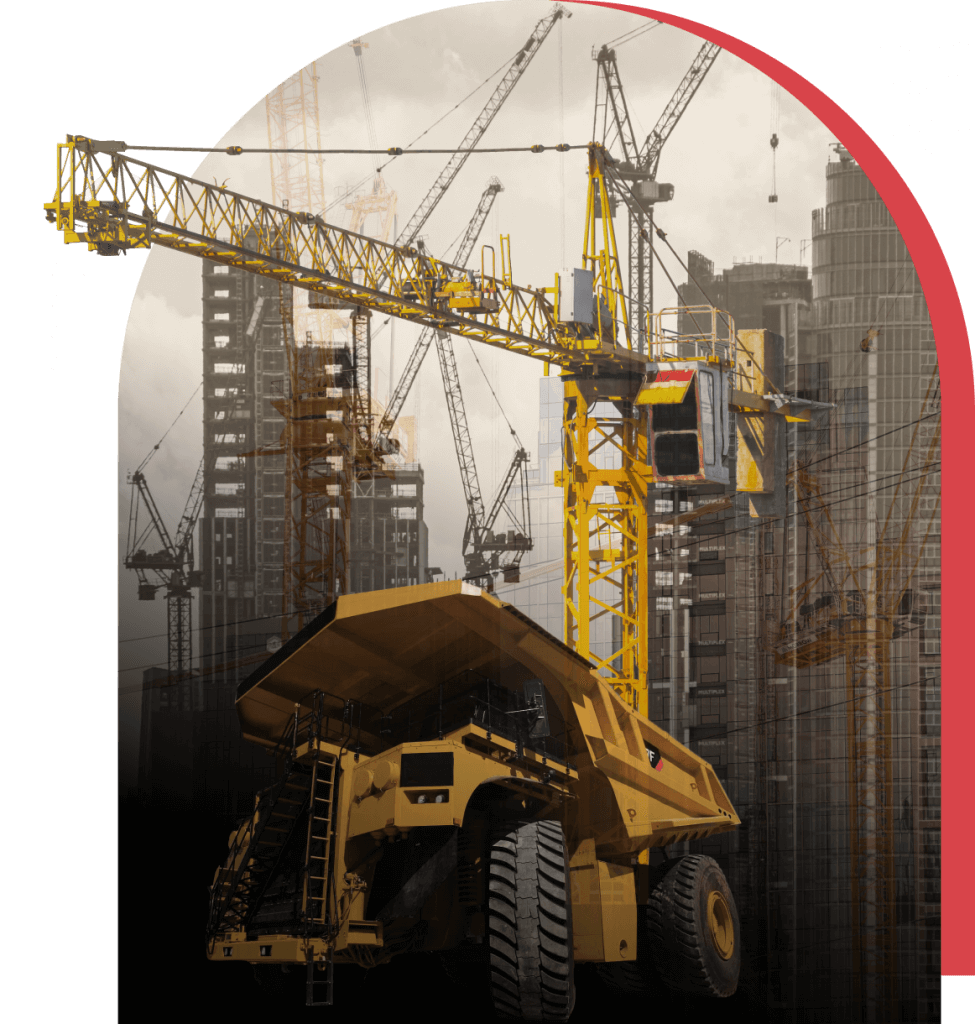

Specializes in offering expertise and turnkey solutions to various industries and contractors associated with the oil and gas, petrochemical, power, and military sectors.

WELCOME TO

MAHATTA TRADING COMPANY W.L.L

A trusted destination for international manufacturers and contractors seeking proficient representation in Kuwait.

Highest Quality

Products & Services

Dominates the market by delivering only the highest quality products. Feel free to contact us to see what we can provide for you.

"Trailblazers of success since 1981!"